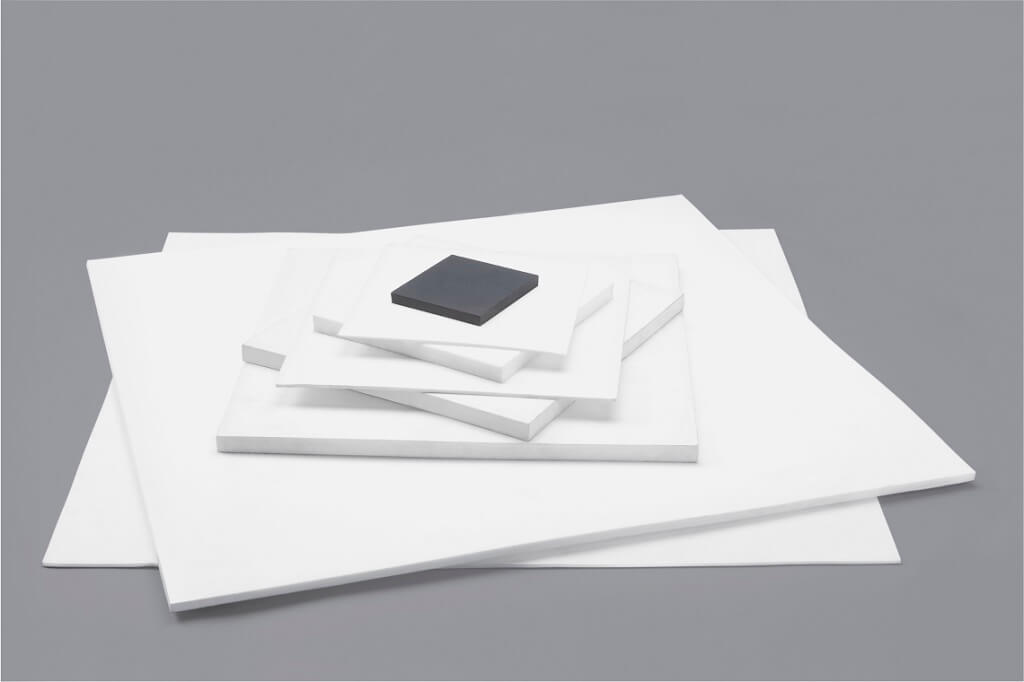

PTFE sheets can be divided into three categories: SFB-1 is mainly used for electrical insulation, SFB-2 is used for corrosive medium gaskets, dense linings, and lubricating materials, and SFB-3 is used for diaphragms in the corrosive medium. According to the different molding processes, it can be divided into two types: molded plate and rotary cutting plate.

The molding method is simpler than the rotary cutting molding equipment, and the production cycle is shorter. However, for large plates, the press mold is larger and the production site space requirements are large. Therefore, a large area of dustproof work must be carried out. In addition, the preformed plate is extremely easy to break. Handle with care before entering the sintering furnace.

PTFE Sheet Production Process

The molding process of large-scale molded plates: raw material inspection → crushing and screening → metering → molding → semi-finished product inspection → sintering → cooling → finished product inspection → packaging.

Process Parameters:

- Raw material processing: crush it through a 10-20 mesh sieve, and place it in an environment of 23℃~25℃ for 24h~48h for temperature adjustment.

- Molding: pressure 1715~35MPa, holding time 1~10min.

- Sintering: the sintering temperature is 360℃~380℃, the heating rate is 30℃/h, the temperature is kept at 330℃ for 2h, and the temperature is kept at 370℃ for 3h.

- Cooling: The cooling rate is 20℃/h, and the temperature is slowly cooled around 330℃ near the melting point of PTFE.

PTFE Sheet Applications

- Take advantage of its good chemical stability. Mainly used for gaskets, linings of large pipelines in petroleum, chemical, and chemical industries, valve discs, diaphragms of large valves, various reaction vessels, storage tanks, reaction tower linings, trays, distribution plates, etc.

- With its excellent dielectric properties, it is used in thermal power stations, electrolyzers, sealing rings, printed circuits in electronic appliances and electronic computer industries, copper-clad substrates, various cutting-edge, and special equipment parts.

- Using its low friction coefficient, it is used for offshore oil drilling derrick slide veneer, dock slide veneer, river dam gate slide veneer, bridge telescopic support slide veneer, various machine tools, boring machines, grinders, Planer sliding guide veneer, etc.

- Using its non-stick properties, it is used in the sugar industry, clothing industry, food, and tobacco baking conveyor belt, printing and dyeing industry anti-sticking, and anti-corrosion coating layer of various guides rollers, etc.

Thanks for the tips shared on the blog. Yet another thing I would like to mention is that weight-loss is not information on going on a dietary fad and trying to lose as much weight that you can in a few months. The most effective way in losing weight is by using it bit by bit and right after some basic points which can provide help to make the most from a attempt to shed pounds. You may learn and already be following most of these tips, nonetheless reinforcing understanding never damages.