The production process of PTFE corrugated hose

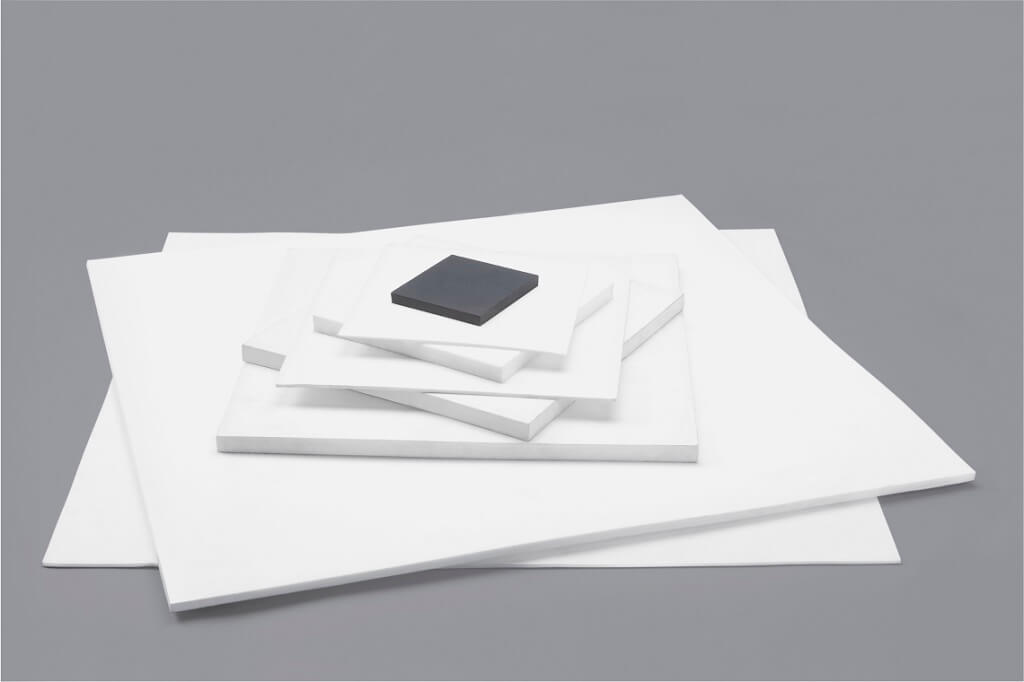

PTFE corrugated hose has been widely used in various corrosion-resistant mechanical seals. The manufacture of the bellows is divided into two steps: first, the blank tube is manufactured and then turned. The PTFE blank tube material consists of three sections, the middle section is pure PTFE, and the two ends are filled PTFE. 1. Raw … Read More